| February 2021 | 1 |

| January 2021 | 1 |

| November 2020 | 1 |

| October 2020 | 3 |

| May 2020 | 2 |

| March 2020 | 5 |

| September 2019 | 1 |

| August 2019 | 2 |

| May 2019 | 3 |

| July 2018 | 1 |

| June 2018 | 2 |

| May 2018 | 23 |

| 2015 Willys 2.5in JKS Lift | Feb 25 2021 |

| 2017 Ford F350 gets a lift | Jan 28 2021 |

| Lifted Adventure Van | Nov 02 2020 |

| 2018 Jeep Wrangler Lifted & Locked | Oct 23 2020 |

| Lifted 2020 Toyota 4Runner | Oct 20 2020 |

| Lifted 2019 Toyota 4Runner with Toytec | Oct 20 2020 |

1989 Toyota Land Cruiser Frame Repair

Check out this beautiful 1989 Toyota Land Cruiser! You might think we’re lying because we didn’t take photos but, the interior is practically mint. While the inside is great, the undercarriage took a beating from years of winter driving. As a result the c-channel frame began growing rust and had some areas of punch through that made it uninspectable. Along with a lot of maintenance related items the customer asked that we repair the frame issues and add a 2” receiver.

Maintenance completed:

- Repair leaking swivel balls

- Replace loose tierod ends

- Replace front & rear leaf spring bushings

- Replace windshield washer fluid pump

- Replace read brake lines and brake wheel cylinders

- Replace battery and retension system

- Replace plug and coil wires

- Oil change

Hard to see the new hitch because the paint is still so fresh!

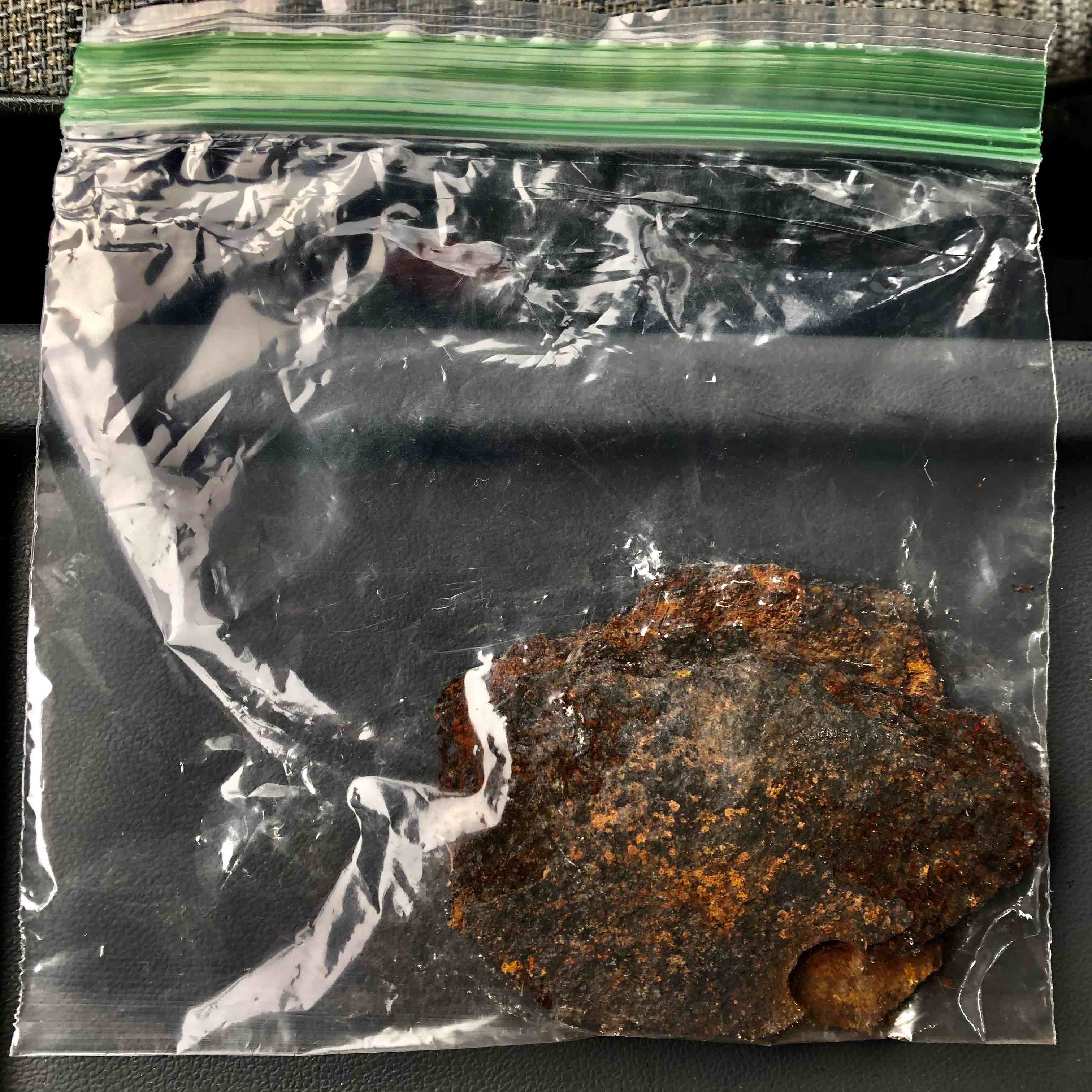

This is what the inner c-channel frame looked like when we put it up on the lift. The frame from the front doors all the way to the bumper pretty much looked like this, some a little better, some much worse. The frame had punch through spots which made it uninspectable even though it was still structurally sound. You get to a point where you have to ask "is it work repairing, or replacing." Truth is, with the structural integrity that remained, we felt the customer was better off to repair. They'll get many great years of use from these repairs.

Braces were made for the c-channel frame and then painted and rust proofed.

The existing frame was descaled and prepped before treating. A layer of fluid film was used between the frame and brace to keep water and debris from getting in between. With the braces in place, bolts were used where the original rivots were, to form a more secure bond.

Everything was painted again and then fluid filmed for extra corrosion protection.

We saved a souvenier for the owner because this frame repair was something most people wouldn't believe without seeing it first hand.